Language

Description

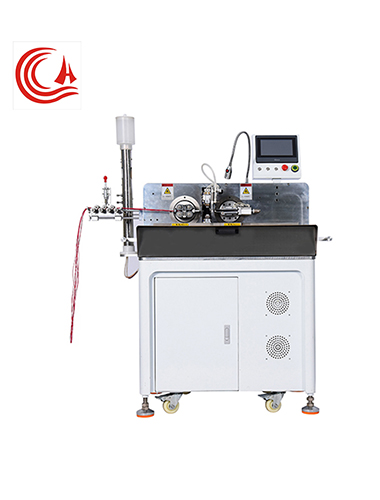

The machine clamp position and soldering tip adjustable to about 10mm.in order to control the soldering wire-side easily bend, more accurate location point dip.Native wetting angle point dip close to 90 degree, wetting average( point dip depth and accurate).High productivty, cutting stripping tinning 8 pcs of wires at the same time.

Processing Capabilities

Cutting

Stripping

Single end twisting

Double ends twisting

Both sides tinning

Special Applications (evaluation required)

Technical Data

Model | HC-20+NT |

Outer dimensions | L1000mm*W600mm*H1200mm |

Weight | 315kg |

Power supply | AC220V/50HZ |

Function | Wire cutting ,Stripping, one end twisting , double ends twisting, double ends tinning |

Display | English / Chinese interface |

Cutting length | 0.1-99999mm |

Cutting tolerances | ±( 0.002×L )mm L : indicates a cutting length. |

Stripping length | 0 mm--10mm |

Applicable wires | AWG32-AWG18 (standard) Optional : up to AWG13

|

Detector | Wire existence,wire overload, strip error,terminal existence, crimp error. Bad crimping |

Compressed Air | 6MPa-7.5Mpa use clean dry air |

Productivity(pcs/h) | 7000-11000pcs/h (wire length within 100mm) |

Sample