Language

structure and principle

1. The pressing mechanism of the clamp is curve propulsion mechanism, and the force is transferred from four curves in the head cavity of the right clamp handle to four blocks, and the block moves in a concentric straight line. Press the front end of the block to press the contact body so that the wire and the contact body are pressed. The four head block moves in harmony, the indentation depth is consistent, and the quality of the wire and contact body is ensured reliably.

2. The internal ratchet claw and rack are used to match the self-locking mechanism to ensure the consistency of the indentation. If the pressure is insufficient or the supply time is too short, the pressure block will not be returned because of the self-locking mechanism. At this time, the pressure should be adjusted or the air supply time should be increased, so that the pressure block moves to the gear position. Return to normal use.

3. The clamp has eight working gears. By lifting the dial (take out the pin first) and rotating, the pointer on the dial is pointed at the corresponding gear, the dial is lowered and confirmed that the dial is flat on the panel, Before we can start work.

Troubleshooting and cautions

1. No rigid steel press joint or a solid or thick cylindrical piece shall be inserted into the pressure tooth cavity to press the joint wantonly, or when a small file is strayed into a large diameter contact body or jammed by a hard object in the tooth cavity, Please contact us.

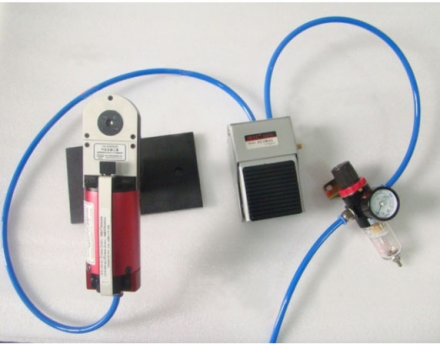

2, working pressure 80-120 P.S. I. Maximum air pressure 120P.S.I. (5.5-8.3bar)

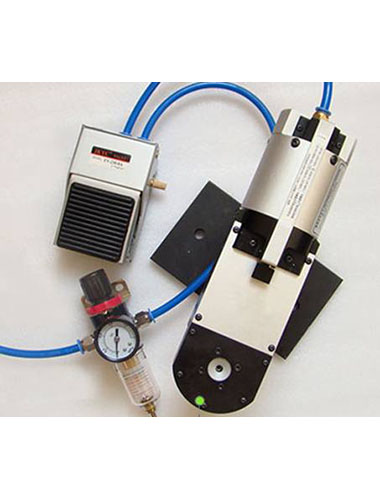

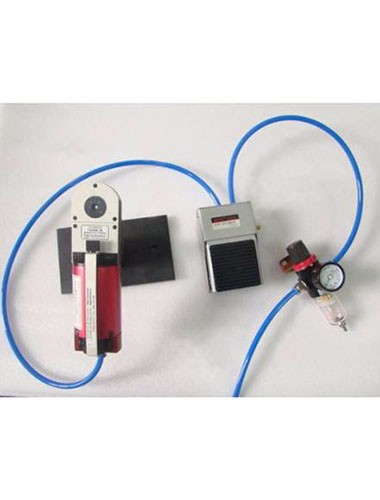

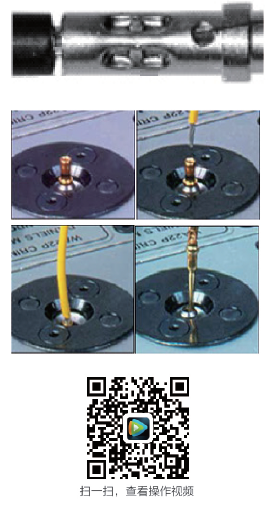

3, press, insert terminals and conductors, supply air to clamp body with pedal switch, release pedal after pressing, press block back in position, remove pressing body and press joint. The following is a sample of clamps.

HC-1Q

HC-1Q

HC-2Q 3Q

HC-2Q 3Q

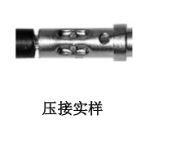

Crimping sample

Crimping sample

Technical data sheet

型号 Type | HC-1Q四点压接机 Four points terminal crimping machine | HC-2Q四点压接机 Four points terminal crimping machine

| HC-3Q四点压接机 Four points terminal crimping machine | |||

适用线径 Wire size | 20 AWG - 32AWG(0.52 mm²-0.03mm²) | 12AWG - 26 AWG(3.33mm²-0.128 mm²) | 8 AWG - 18 AWG(8 mm²-0.8 mm²) | |||

调节盘档位 Adjustment plate gear | 压头工作直径INCH/mm Crimp head diameter | 压头工作直径INCH/mm Crimp head diameter | 压头工作直径INCH/mm Crimp head diameter | |||

通 (on) | 止 (off) | 通(on) | 止(off) | 通(on) | 止(off) | |

1 | 0.7/0.028 | 0.84/0.033 | 0.7/0.028 | 0.84/0.033 | 0.036/0.91 | 0.041/1.04 |

2 | 0.81/0.032 | 0.94/0.037 | 0.81/0.032 | 0.94/0.037 | 0.045/1.14 | 0.05/1.27 |

3 | 0.91/0.036 | 1.04/0.041 | 0.91/0.036 | 1.04/0.041 | 0.052/1.32 | 0.057/1.45 |

4 | 0.99/0.039 | 1.12/0.044 | 0.99/0.039 | 1.12/0.044 | 0.061/1.55 | 0.066/1.68 |

5 | 1.14/0.045 | 1.27/0.050 | 1.14/0.045 | 1.27/0.050 | 0.069/1.75 | 0.074/1.88 |

6 | 1.32/0.052 | 1.45/0.057 | 1.32/0.052 | 1.45/0.057 | 0.076/1.93 | 0.081/2.06 |

7 | 1.50/0.059 | 1.63/0.064 | 1.50/0.059 | 1.63/0.064 | 0.086/2.18 | 0.095/2.41 |

8 | 1.73/0.068 | 1.86/0.073 | 1.73/0.068 | 1.86/0.073 | 0.1/2.54 | 0.11/2.79 |

scan QR code to watch video

scan QR code to watch video

![5201552466167751.jpg )`FQG7Y%BXGJ[(R]8F[TBQ2.jpg](/muploadfiles/128.1.164.27/webid1117/uploadimage/201903/5201552466167751.jpg)